Our YouTube channel includes detailed installation guides, frequently asked questions, product overviews and lots more. We are always open to content ideas so please let us know if there is a topic you would like us to cover.

The Benefits of Tensile Architecture for Large-Scale Projects

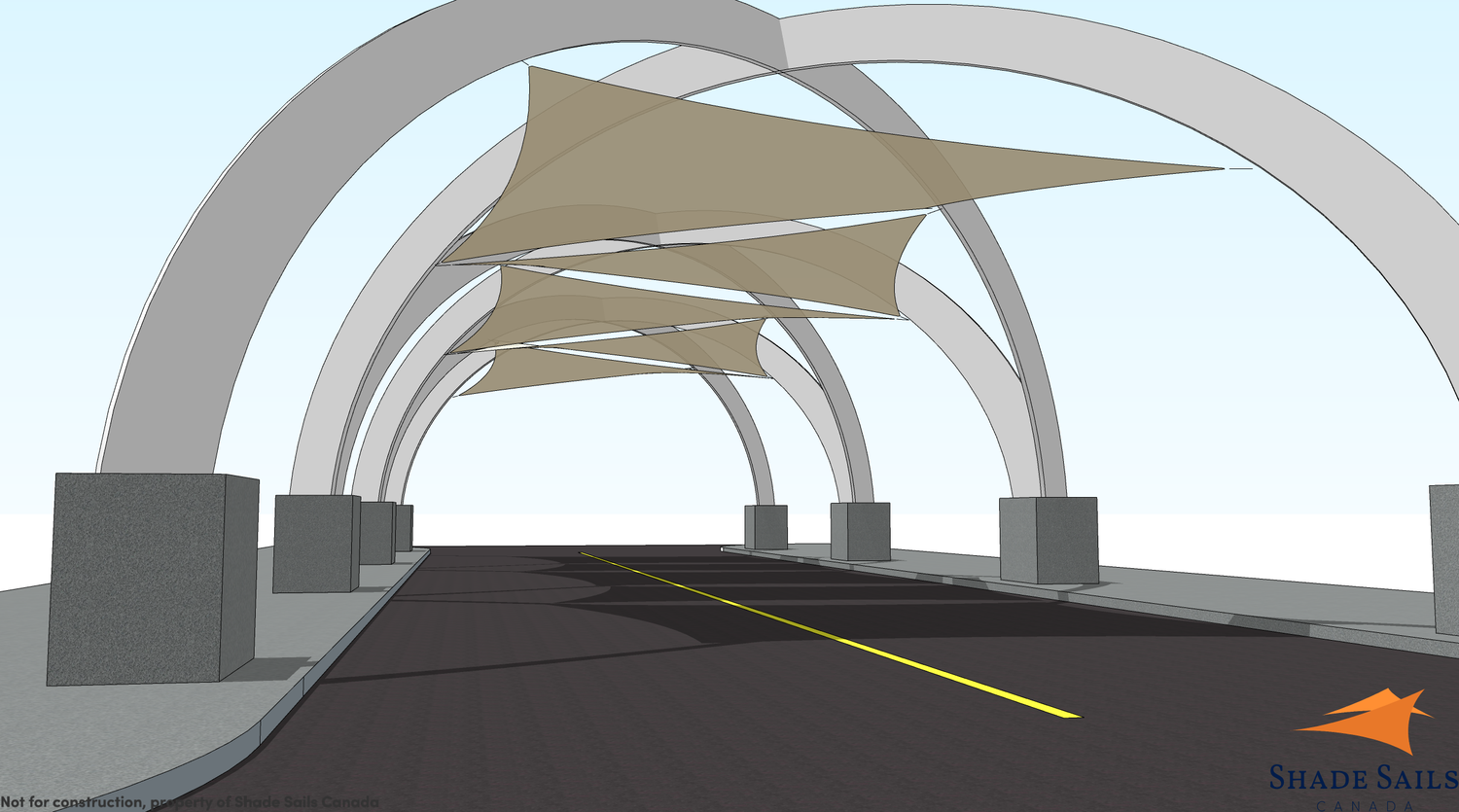

In today's architectural landscape, tensile structures have emerged as a transformative solution for large-scale projects. This unique form of architecture uses tensioned membranes to create lightweight, durable, and aesthetically pleasing structures.

Tensile architecture has gained immense popularity due to its versatility and the myriad of benefits it offers. In this article, we delve into the advantages of employing tensile structures in large-scale projects and explore their various applications in modern architectural designs.

Clear Advantages of Tensile Architecture

Superior Flexibility and Design Versatility

One of the most compelling reasons to consider tensile architecture for large-scale projects is its unparalleled flexibility. This architectural style allows for the creation of dynamic, fluid shapes that are often impossible with traditional construction methods.

Adaptability: Tensile structures can adapt to various forms, sizes, and functionalities, making them suitable for a wide range of applications such as stadiums, exhibition halls, and airports.

Aesthetic Appeal: The sleek, modern look of tensile structures can enhance the visual appeal of any project, enabling architects to push the boundaries of conventional design.

Cost-Effectiveness and Efficiency

When it comes to budget and project timelines, tensile architecture stands out as an economical choice compared to traditional methods of steel and timber construction.

Reduced Material Costs: Tensile structures require less material compared to traditional building methods, resulting in lower material costs.

Quick Installation: The construction and installation process for tensile structures is typically faster, leading to reduced labor costs and shorter project durations.

Concise Insights into Tensile Structure Applications

Tensile architecture is not confined to a single type of project but has a wide array of applications, each benefiting from its unique attributes.

Sports Venues: Large stadiums and amphitheaters often employ tensile structures for their roofing systems, providing spectators with unobstructed views and minimizing support columns.

Public Spaces: Airports, convention centers, and exhibition halls have increasingly adopted tensile structures to create spacious, light-filled, and welcoming environments.

Commercial Buildings: Retail spaces and office complexes benefit from tensile structures' capacity for creating large, open interior spaces without the need for intrusive support beams.

Compelling Benefits of Tensile Structures Explained

Environmental Sustainability

In an era where sustainability is paramount, tensile architecture represents an eco-friendly alternative with many of the materials used being recyclable.

Energy Efficiency: The lightweight nature of tensile structures results in lower energy consumption for heating and cooling.

Recyclable Materials: Many of the materials used in tensile structures, such as PTFE-coated fiberglass and ETFE foil, are recyclable, contributing to lower environmental impact.

Durability and Maintenance: Tensile structures are not only visually appealing but also robust and long-lasting, offering years and years of lifespan.

Weather Resistance: Modern tensile structures are designed to withstand extreme weather conditions, including high winds and heavy snow loads.

Low Maintenance: The materials used in tensile structures are typically resistant to UV radiation, mildew, and dirt, requiring minimal maintenance over their lifespan.

Credible Information Addressing FAQs

How long do tensile structures last?

The durability of tensile structures can often exceed 30 years, depending on the materials used and environmental conditions.

What kind of maintenance do tensile structures require?

Tensile structures are generally low-maintenance, necessitating periodic inspections and cleaning to ensure their longevity and performance.

Are tensile structures suitable for extreme climates?

Yes, tensile structures are engineered to perform well in various climate conditions, from tropical environments to cold and snowy regions.

FAQ: Tensile Structures in Large-Scale Projects

What are the advantages of using tensile structures in large-scale projects?

Tensile structures, characterized by their lightweight and flexible materials, offer numerous advantages for large-scale projects. Some of the key benefits include:

Lightweight and Strength: Tensile structures use materials like high-strength steel cables and membrane fabrics, offering a high strength-to-weight ratio. This allows for large spans with minimal support, ideal for vast spaces like stadiums, exhibition halls, and airports.

Versatility: The flexibility of the materials allows for creative and innovative designs that can adapt to various architectural needs, from dramatic roof shapes to flowing façades.

Transparency and Natural Light: Tensile membranes can be designed to allow for varying degrees of light transmission. This capability can reduce reliance on artificial lighting, thereby saving energy and creating pleasant interiors illuminated by natural light.

Durability and Low Maintenance: Materials used in tensile structures, such as PTFE-coated fiberglass or PVC-coated polyester, are resistant to weather, UV radiation, and pollutants. They require minimal maintenance compared to traditional building materials like glass or steel.

Quick Installation: The prefabrication of tensile elements off-site followed by rapid on-site assembly reduces construction time significantly. This advantage is crucial for projects that require fast completion, minimizing interruptions in congested urban areas or ongoing operations.

How does tensile architecture contribute to efficiency in large-scale projects?

Tensile architecture enhances efficiency in multiple ways:

Minimized Resource Use: The efficiency begins with the manufacturing process. Tensile structures use less material compared to conventional construction methods, reducing overall resource consumption.

Enhanced Environmental Control: The flexibility in design allows for better management of environmental factors such as light, heat, and sound. Membranes can incorporate insulation properties to regulate temperatures effectively, leading to reduced energy consumption and operating costs.

Speed of Construction: The lightweight nature of tensile materials facilitates fast transport and installation. This speedy construction method decreases labor costs and shortens project timelines, translating to quicker returns on investment.

Adaptability: Tensile structures can be designed for easy modification, relocation, or expansion, making them suitable for evolving project requirements. Their adaptability ensures the longevity of the structure in terms of utility and relevance.

What makes tensile structures a cost-effective choice for large-scale projects?

Tensile structures provide cost-effectiveness through various mechanisms:

Material Efficiency: The high strength-to-weight ratio means less material is required to cover large spans. This aspect reduces both the material costs and the structural support requirements (like heavy pillars or beams).

Reduced Foundation and Support Costs: The lightweight nature of tensile materials means that foundations and support structures can be lighter and less expensive compared to those required for traditional materials.

Maintenance Savings: Tensile membranes are durable and require minimal upkeep. This low maintenance reduces long-term operational costs compared to traditional building materials, which can be prone to corrosion, cracking, or other forms of degradation.

Energy Savings: By utilizing natural light and incorporating thermal or solar properties, tensile structures can significantly cut down on energy expenditures for heating, cooling, and lighting.

Shorter Construction Duration: Fast-track construction processes can drastically reduce labor costs and the expenses associated with on-site duration, such as equipment rental, insurance, and project management fees.

In what ways can tensile structures improve the aesthetic appeal of large-scale projects?

Tensile structures can dramatically enhance the visual and architectural appeal of large-scale projects through several features:

Dynamic Forms: The inherent flexibility of tensile materials allows for the creation of unique, flowing, and dynamic shapes that are not achievable with rigid materials. This versatility can make a structure stand out as an iconic landmark.

Expressive Curvature and Sleek Lines: The fluidity of tensile structures can create smooth, unbroken lines and elegant curves that contribute to a modern and sophisticated appearance.

Translucency and Illumination: The semi-translucent nature of certain tensile membranes allows for stunning light effects, including diffused daylight during the day and backlighting at night. This interplay between light and material can create a captivating ambiance.

Customizable Aesthetics: Tensile materials can be produced in a variety of colors and textures, allowing architects to tailor the aesthetic to the project’s specific needs. This adaptability can reflect corporate branding or thematic elements.

Integration with Surroundings: The lightweight and unobtrusive nature of tensile structures can easily blend with natural environments or complement contemporary urban landscapes, adding to the overall visual coherence of the project.

Conclusion

Tensile structures offer a versatile, cost-effective, and sustainable solution for large-scale architectural projects. Their flexibility in design, ease of installation, and durability make them an ideal choice for a wide array of applications, from sports venues to commercial complexes.

As we continue to seek innovative and sustainable architectural solutions, tensile architecture stands out as a compelling option. Embracing tensile structures not only enhances the aesthetic and functional aspects of projects but also provides a credible and sensible approach to modern construction needs.